Digital Printing Fundamentals Explained

Digital Printing Fundamentals Explained

Blog Article

Facts About Digital Printing Revealed

Table of ContentsGet This Report on Digital PrintingUnknown Facts About Digital PrintingThe Definitive Guide to Digital Printing

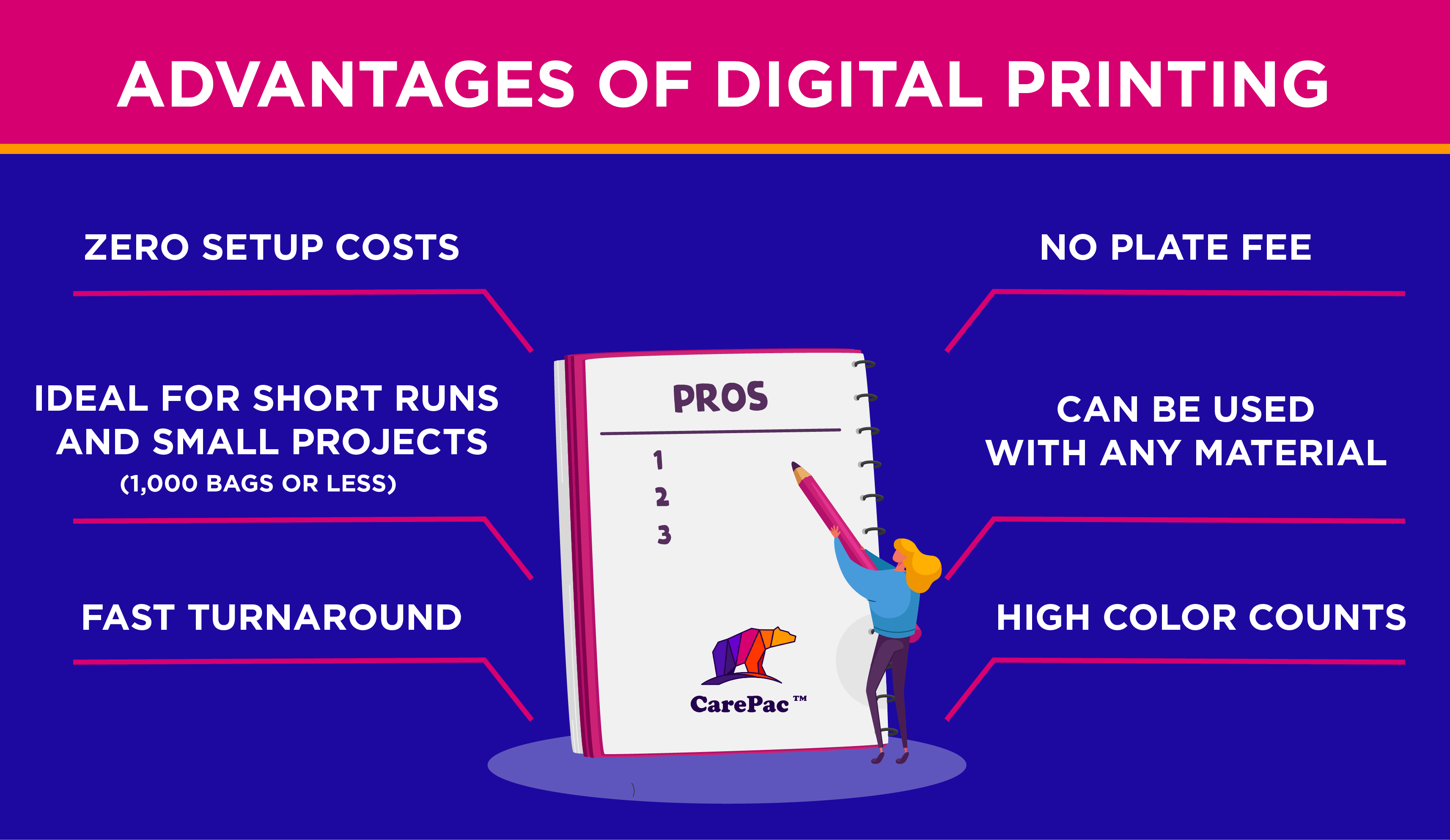

The liquid ink sticks to the substratum through an electrostatic cost, guaranteeing vibrant colours and sharp detail. Digital printing also requires marginal setup. Although contemporary lithographic technology has actually reduced arrangement times to around 15 mins, digital printing still results in benefit with its near-instant readiness. Furthermore, electronic prints completely dry instantly, unlike lithographic prints, which call for 2-3 hours to completely dry. This eliminates smearing dangers and the demand for drying out racks. Right here are the essential means in which electronic printing sustains greener techniques: Among the considerable environmental advantages of electronic printing is lowering waste. Conventional printing approaches, like lithographic printing, usually waste considerable quantities of paper and ink throughout the setup phase. Digital printing removes the need for plates and other consumables, minimizing waste throughout the production process. Some of one of the most common applications include: Digital printing is best for developing calling card, leaflets, posters and other marketing materials. It enables fast turn-around times and affordable production, especially for businesses with smaller print runs. Digital printing is increasingly made use of in the packaging market to develop unique, custom-made product packaging.

Digital printing machine remove the need for these plates, dramatically reducing configuration costs. Digital printing machine can incorporate variable information into your prints, which permits extremely customized marketing products (Digital Printing). By customizing your advertising and marketing materials, you can enhance interaction with possible customers and enhance the opportunities of converting them into real consumers

Digital printing machine provide excellent color uniformity and precision, causing higher quality prints. With digital printing, you can be certain that the shade of your prints will certainly be consistent from one print job to the next. Several years back, lots of clients did decline direct-injection digital printing due to the fact that the high cost. The acquisition cost of an established digital printing devices is at least 150%of the typical printing and coloring devices, which enhances the.

Digital Printing - An Overview

Therefore, printers must utilize more fluid inks to stop nozzle clogging and printhead failure. In order to stop deterioration of the nozzle, the ink for electronic printing is more costly than the ink for typical printing, and added ink purification is essential throughout the printing procedure. Additionally, the benefit of digital inkjet printing is apparent only when utilizing inks with a huge color gamut. The electronic inkjet printing machine practically realizes the automatic control procedure. In electronic inkjet printing, the pattern is straight published on the material, eliminating the plate making in rotary screen printing. It not only saves the useful time of plate making, however likewise saves the additional expense of plate production. At the same time, increasingly more brand Check Out Your URL names are now increasingly more accepting of paying greater expenses for faster shipment, such as providing a set of materials within a week or perhaps 3 days, rather than weeks and months - Digital Printing. Yes, are more pricey than standard printing inks, but the digital printing procedure can save ink intake.

Today, the electronic direct-injection printing equipment has actually gone from proofing to the stage of medium-sized and large-sized manufacturing. Both printing houses and brand proprietors are mindful of the growth capacity of digital printing, and are willing to increase investment in digital printing. Digital printing is a lot more cost-efficient for brief click over here now print runs due to the fact that it needs much less pre-press tasks and less setup than countered printing.

Variable information printing, such as straight mail with personalized codes and addresses, is preferably matched for digital printing. Digital quick printing just needs 4 steps of design, testimonial, printing and binding to get every little thing done. Digital quick printing has an unparalleled benefit: print on need.

Report this page